Service Details

- home

- Double Wheel Swing Roller

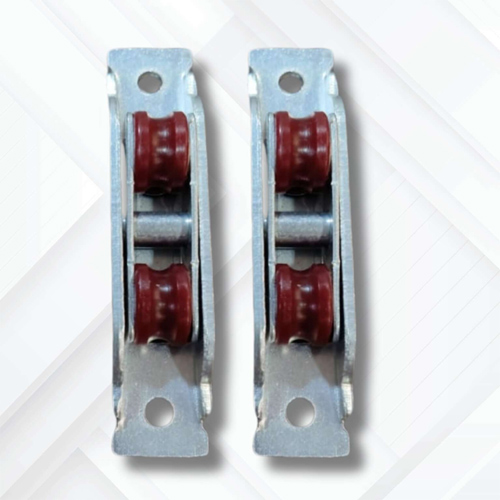

Double Wheel Swing Roller

The Double Wheel Swing Roller, also commonly referred to as a double swing wheel or tandem roller, is a specialized hardware component essential for the smooth and reliable operation of modern sliding doors and windows, particularly in uPVC (unplasticized polyvinyl chloride) and aluminium systems. Its dual-wheel configuration and unique 'swing' mechanism offer significant advantages over traditional single rollers.

Key Components and Function

A typical Double Wheel Swing Roller unit consists of several integral parts that work together to facilitate smooth horizontal movement:

- Dual Wheels: The defining feature is the presence of two rollers (wheels) mounted side-by-side. These wheels are often made from high-density, low-friction materials like Nylon (Polyamide) or POM (Polyoxymethylene/Acetal Delrin) for silent operation and durability. They may be flat or grooved depending on the specific track design.

- Roller Carriage/Housing: This is the frame, typically made of durable material like stainless steel (SS), zinc alloy, or aluminium, that securely holds the two wheels.

- Swing Mechanism (Bogie System): The "swing" or "bogie" feature allows the pair of wheels to pivot or rock slightly within the carriage. This is crucial for maintaining contact with the track even if the track has minor undulations or imperfections, ensuring the load is distributed evenly across both wheels.

- Bearings: Precision bearings (e.g., 626ZZ) are often incorporated into the wheels to reduce friction and allow for effortless sliding.

- Adjustment Mechanism (Optional): Many heavy-duty double rollers are adjustable. A built-in fastener allows the installer or user to raise or lower the door/window frame slightly for precise alignment and to compensate for wear over time.

The primary function of the roller is to support the considerable weight of the sliding door or window sash and allow it to glide effortlessly along the bottom track, ensuring a quiet, smooth, and secure opening and closing action.

Advantages Over Single Rollers

The double wheel design offers several key performance enhancements:

- Enhanced Load Capacity: By distributing the load over two contact points instead of one, the double roller can handle significantly heavier doors and windows—often supporting maximum capacities up to 90 kg, 120 kg, or even more per pair, making them essential for large patio doors or multi-track stacking systems.

- Improved Stability: The wider footprint and dual contact points provide greater stability, reducing the chances of the door wobbling, tilting, or derailing, especially when fully opened or closed.

- Smoother Operation: The swing mechanism, especially in conjunction with low-friction materials, ensures smoother and quieter movement across the track, even if the track surface is not perfectly level. The independent rotation of the two wheels also reduces the 'scrubbing' effect during turns, making movement easier.

- Increased Durability and Lifespan: The load is spread out, which reduces the stress and wear on each individual wheel and bearing, resulting in a longer service life and less frequent need for maintenance or replacement.

Application and Installation

Double Wheel Swing Rollers are primarily used in heavy-duty applications such as:

- uPVC Sliding Patio Doors

- Heavy Aluminium Sliding Doors

- Large or Multi-Panel Sliding Windows

Feel free to contact us with any questions or concerns

you may have. We’ll always be happy to assist.

- 9220233993

- info@zyolo.in